Have you ever heard of the term ‘Plastic Wood’?

‘Plastic Wood’ is a common name for a type of wood filler or substitute material that is often used in home improvement and repair projects.

Despite its name, it is not really made of plastic, nor is it a solid piece of wood.

Instead, it is a man-made material designed to look, feel, and act like real wood once it dries and hardens.

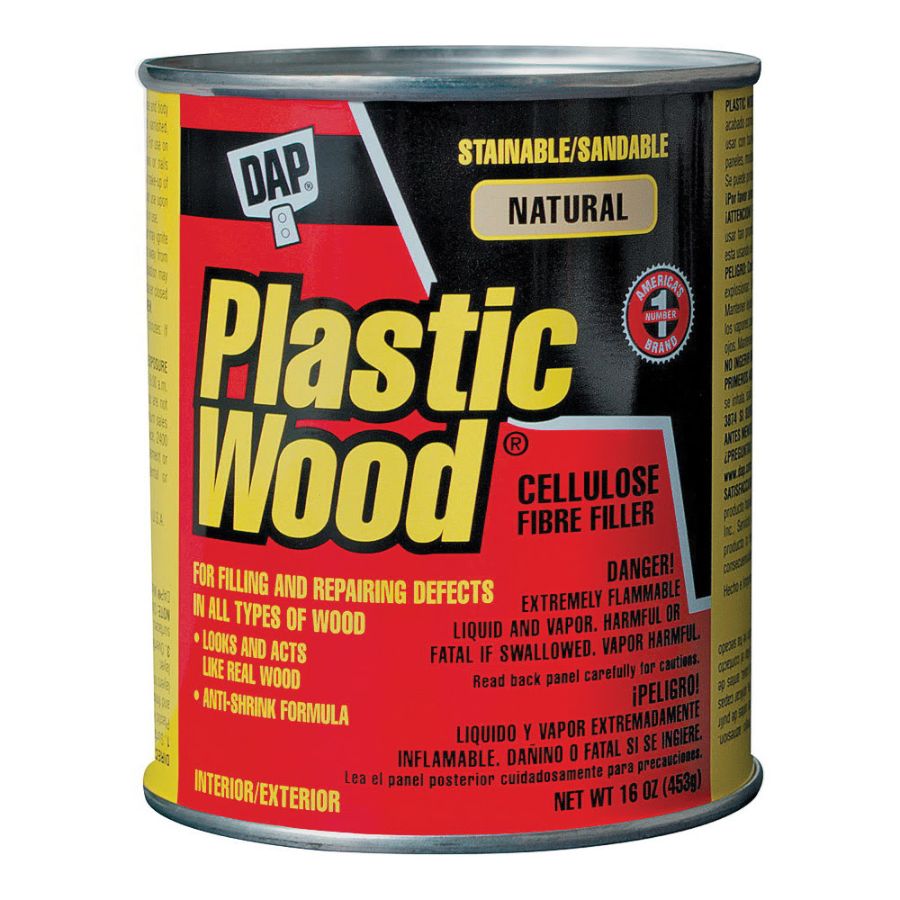

The most famous brand of this product is made by DAP, which has been selling it for decades.

Over time, the name “Plastic Wood” has become so familiar that many people use it to describe any kind of wood filler, even if it is from another company (think along the lines of how folks often refer to a ‘Kleenex’ when they are really referring to a ‘facial tissue’).

At its core, Plastic Wood is a putty-like substance that usually comes in a small can or tube.

It is made from a mixture of wood fibers, binders, and solvents. The wood fibers give it a natural appearance and allow it to be sanded, painted, or stained to match real wood. The binders and solvents act like glue, holding the fibers together and helping the filler harden after it is applied. This mixture makes it an ideal product for fixing cracks, holes, dents, or scratches in wooden furniture, floors, doors, and trim.

Using Plastic Wood is fairly simple.

When you have a hole or gap in a wooden surface, you scoop out some of the filler and press it into the damaged spot with a putty knife. You then smooth out the surface and let it dry.

Depending on the product and the size of the repair, drying can take anywhere from a few minutes to several hours.

Once hardened, the filler becomes tough and durable, much like real wood. After that, it can be sanded smooth, painted, or stained so that the repair blends in with the surrounding surface.

One of the biggest advantages of Plastic Wood is how versatile it is.

Plastic Wood works well indoors and, in many cases, outdoors too.

People use Plastic Wood on wooden furniture, cabinets, windowsills, and even hardwood floors. If applied properly, the repair can be nearly invisible once finished. For homeowners and carpenters, this makes it a go-to product for quick and effective fixes.

Plastic Wood does have some limits.

Because Plastic Wood is a filler and not real solid wood, it is not always as strong as the original material.

Large structural repairs, like fixing broken chair legs or beams, are not good uses for it nor is it the best solution for repairing exterior horizontal surfaces (think decks & porch floors). In those cases, real wood replacements or stronger adhesives or epoxy repair systems may be needed.

Also, since the filler can shrink slightly as it dries, sometimes a second layer must be added to get a perfectly flush surface.

Environmentally, Plastic Wood is a bit of a mixed story.

On one hand, using a filler allows people to repair items instead of throwing them away, which reduces waste.

On the other hand, it is a manufactured product that contains chemicals and solvents, which means it is not as natural or sustainable as pure wood. Still, for small repairs, it offers a practical way to extend the life of wooden objects and save money.

Plastic Wood is a man-made wood filler designed to look and act like real wood once it dries and has become a trusted product in woodworking and home repair.

While Plastic Wood may not be suitable for every single wood repair, it is certainly an excellent solution for a wide variety of cosmetic and surface-level repairs.

Follow Us on Social Media!